Student Work Lecture Story

On 29 June-1 July 2022, the 2018 Bioenergy Engineering and Chemurgy Students carried out work lectures. This work course is a program that will be held annually by students of ITB Bioenergy Engineering and Chemurgy. In this work course, students will visit several factories in various industrial sectors. This activity is designed in such a way that all students of Bioenergy Engineering and Chemurgy ITB get an overview of their respective fields of work. The 2018 Bioenergy Engineering and Chemurgy Work Lecture is an opportunity for students of Bioenergy Engineering and Chemurgy class 2018 to get an idea of the application of the sciences that have been studied for three years. By knowing earlier about the application of Bioenergy Engineering and Chemurgy in the workplace, students of Bioenergy Engineering and Chemurgy are expected to get more motivation to study so that they can study enthusiastically and later become full-fledged Bioenergy Engineering and Chemurgy graduates. The factory we visited was PT. Indesso Aroma in Banyumas and PT. Madubaru in Yogyakarta.

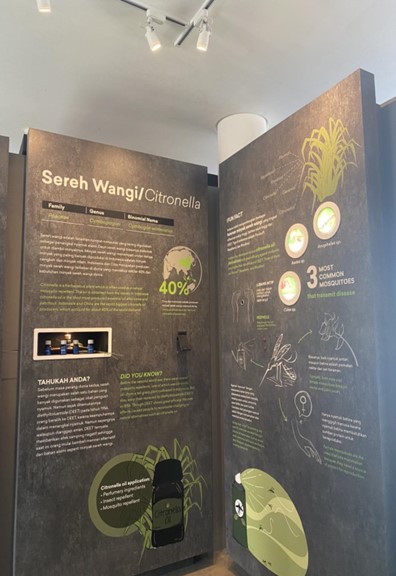

On the first day, Wednesday (29 June 2022), Bioenergy Engineering and Chemurgy students class 2018 (TB’18) carried out an industrial visit to PT Indesso Aroma, Batu Raden, Banyumas and PT Indesso Aroma is a company engaged in flavor and fragrance. At around 09.00 WIB, the TB’18 group arrived at the location and was warmly welcomed by Indesso Aroma. We were directed to a special room to get an explanation about the company profile presented by Mr. Ari. The presentation was very interesting and added to our insight about the beginning of the establishment of PT Indesso Aroma, the products produced, to the processes and innovations carried out by PT Indesso Aroma. After getting an explanation of the company profile, we headed to the second floor which showed information and examples of raw materials and products produced by PT Indesso Aroma. After we finished looking around on the second floor, we headed to the 3rd floor to see the application of the products produced by PT Indesso Aroma, the eugenol production area from clove oil to the quality control room. Then we were invited to go outside to see the plantation owned by PT Indesso Aroma and the waste water treatment area. After we were satisfied walking around we were invited to the rooftop to taste the tempe mendoan and also enjoy the natural scenery and Mount Slamet.

On the second day, Thursday (30 June 2022), TB’18 visited the sugar factory and the spirit alcohol factory of PT. Madubaru in Bantul, Yogyakarta. This factory was founded in 1955 (construction by North Germany). PT. Madubaru has 6000 hectares of land planted with sugar cane. The process that occurs at this factory starts from sugar cane processing by weighing and measuring sugar content. If the sugar content of sugar cane is high, it is taken to the sugar factory, but when the sugar content is low, it is taken to the alcoholic spirit factory. To get to the factory area, visitors are taken via recreational trains. The explanation of the process when in the factory was delivered by Mr. Suryo Budi. We were invited to tour the sugar factory and the spritus factory. We visited the sugar factory first. In the sugar factory, sugar will undergo a milking process to separate the juice from the pulp. Then the sap will undergo a purification process with a continuous alkaline sulfitation system. The dirty sap from the reservoir will be sucked by a rotating cylinder, for low vacuum conditions dirty filtrate is obtained, while for high vacuum clean filtrate is obtained. The clear sap will then be heated to a temperature of 100-105 C. The next process is the evaporation of the sap which aims to evaporate a large amount of water contained in the diluted sap so that thick sap is obtained. Then, the thick sap will undergo a crystallization process to facilitate the storage and separation of dirty sugar in the screening section. The last process is the spinning process using centrifugal force which aims to separate the sugar and the solution.

Next we were invited to tour the sprites factory. In the spritus factory, the initial process of making spritus is cooking which includes the process of diluting the addition of acids and food substances. The drops from PG Madukismo are still very concentrated, so they need to be diluted to get the optimum sugar content. The next process is the nursery process using Saccharomyces cerevisiae cells. Next is the fermentation process (fermentation) or alcoholic fermentation process under anaerobic conditions so that yeast cells are expected to be able to carry out fermentation which will convert sugar-containing molasses into alcohol. The last process is the process of distillation or distillation which aims to separate the mixture through different boiling points. While wandering around the sugar factory and spirit factory, we tried one of the products from PT. Madubaru is a hand sanitizer with various variants such as coffee, original, mango, melon, and cucumber.